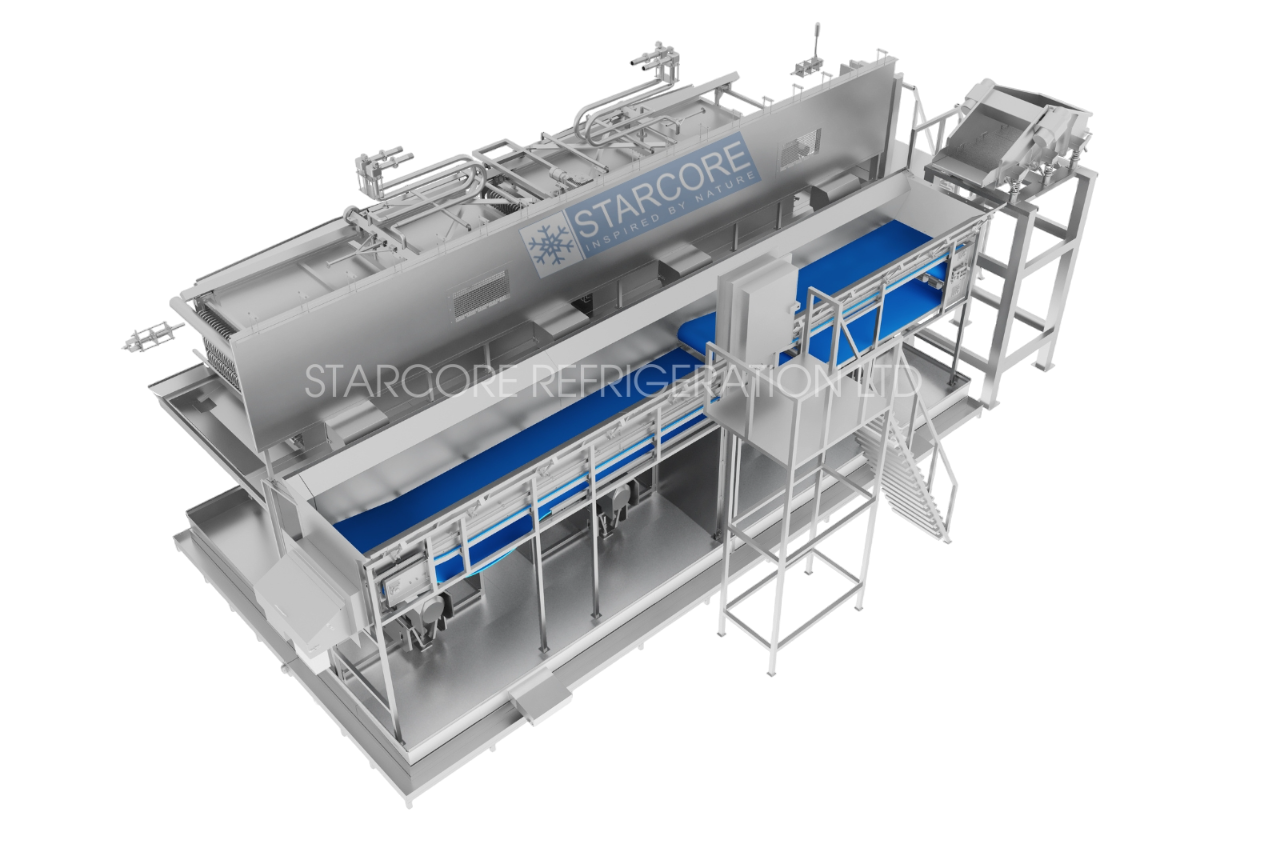

The INDIVIDUAL QUICK FREEZER was pioneered by STARCORE REFRIGERATION LTD to meet the growing demand for packaged frozen fruits and vegetables in the nascent Indian market. Since then, STARCORE has engineered IQFs to put India on the map of global frozen food production.

With the advent of technology upgradation, adopting the latest in Mechatronics engineering and integrative AI, Starcore has engineered the latest Adaptive & Intelligent Control systems for the IQF freezer.

Starcore utilizes efficient system control engineering to define the following:

Capacities ranging from 0.5 MT/HR to 8MT/HR of diced fruits, vegetables, paneer, cheese, French fries, cooked rice, rose petals and nectarines.

Can be worked with R404A / R707 / R744 A pumped recirculation systems with operating evaporation temperatures at -5 to -55 Deg C.

All parts can be archived with part numbers and part code on our ERP system, which even after the model is upgraded is available for our customers. Customers can buy spare parts from us along with lubricants and consumables.

We give services ON CALL, PREVENTIVE MAINTAINANCE, QUATERLY AND YEARLY SERVICE so that your business does not run out of fuel.

STARCORE REFRIGERATION LTD. was founded by Mr. Kartik Nagarajan and Mrs. Ramachandran Padmavathi in the year 2012. India was very new to the frozen food processing business, and only a few companies were able to freeze agricultural produce that would otherwise decay if not in demand or consumed.