STARCORE DESIGNS SPIRALS FOR THE FOLLOWING APPLICATIONS:

We started building spirals two decades back and have vast experience in material handling along with control and automation, reinforced with different types of cooling methodology for your delicate and tasty products. Right from controlling the cooling rate, and dwell times of product inside the spiral to tension control and safeties of the drive belt we have mastered it all. The Spiral is an advent of low space. low power consumption does away with long straight belts which would have consumed a lot of real estate and more power per kg of freezing/cooling/proofing as the process may be.

The Spiral system should be built with an intelligent control system, which can prevent accidents, and food losses, and incorporate easy cleaning modes along with effective defrost systems. The spiral food machine is an automated system with very little manpower interface, which has been possible because of its AI system which measures in a PID loop various parameters like Current, Torque, tension, Frequency, Speed and gain.

The numerical code runs the system in synchronisation with utility operations, exactly to a decimal, making the moth machine gyrate around its drive, as your product moves to complete its journey in the programmed dwell time.

Starcore utilizes efficient system control engineering to define the following:

100, 250, 500 , 1000 , 1500, 2000 , 3000, 5000 kg/hr spiral with single or double drum configurations available for all your creations.

Can be worked with R404A / R707 / R744 A pumped recirculation systems with operating evaporation temperatures at -5 to -55 DegC.

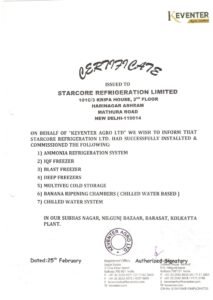

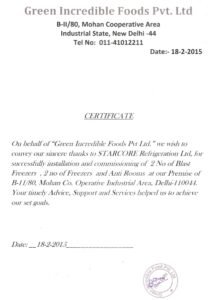

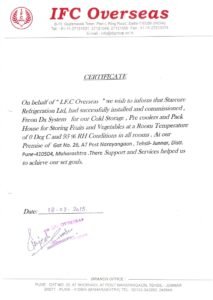

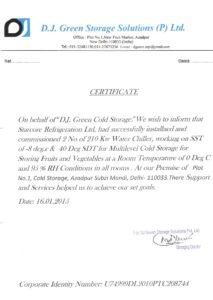

STARCORE REFRIGERATION LTD. was founded by Mr. Kartik Nagarajan and Mrs. Ramachandran Padmavathi in the year 2012. India was very new to the frozen food processing business, and only a few companies were able to freeze agricultural produce that would otherwise decay if not in demand or consumed.